Wearable technology has evolved dramatically from simple step counters to sophisticated devices that monitor, connect, and improve lives in real time. A major driver of this transformation is the emergence of printed electronics. Unlike traditional rigid components, printed electronics use conductive inks and flexible materials to create thin, lightweight, and adaptable circuits, perfectly suited for wearables.

This article explores how printed electronics are powering the next generation of wearable devices, their benefits, and their expanding role in industries like healthcare, fitness, and beyond.

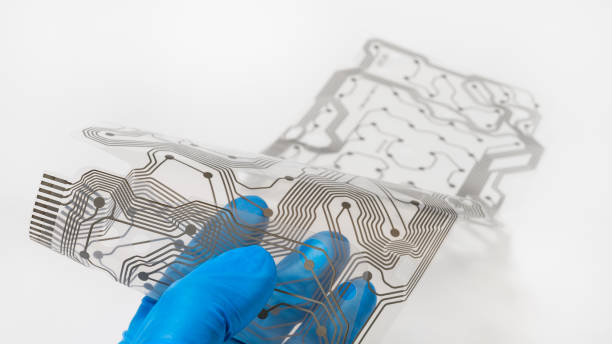

What Are Printed Electronics?

Printed electronics are created by depositing conductive or functional inks—often made from materials such as silver, carbon, or graphene—onto flexible substrates like plastic films, fabrics, or paper. These inks form circuits, sensors, batteries, and displays when layered and patterned correctly.

Unlike traditional silicon-based components, printed electronics are:

Extremely thin and lightweight

Flexible and sometimes stretchable

Cost-efficient to manufacture at scale

Easy to customize for different shapes and materials

These features make them ideal for wearables, where comfort and design flexibility are crucial.

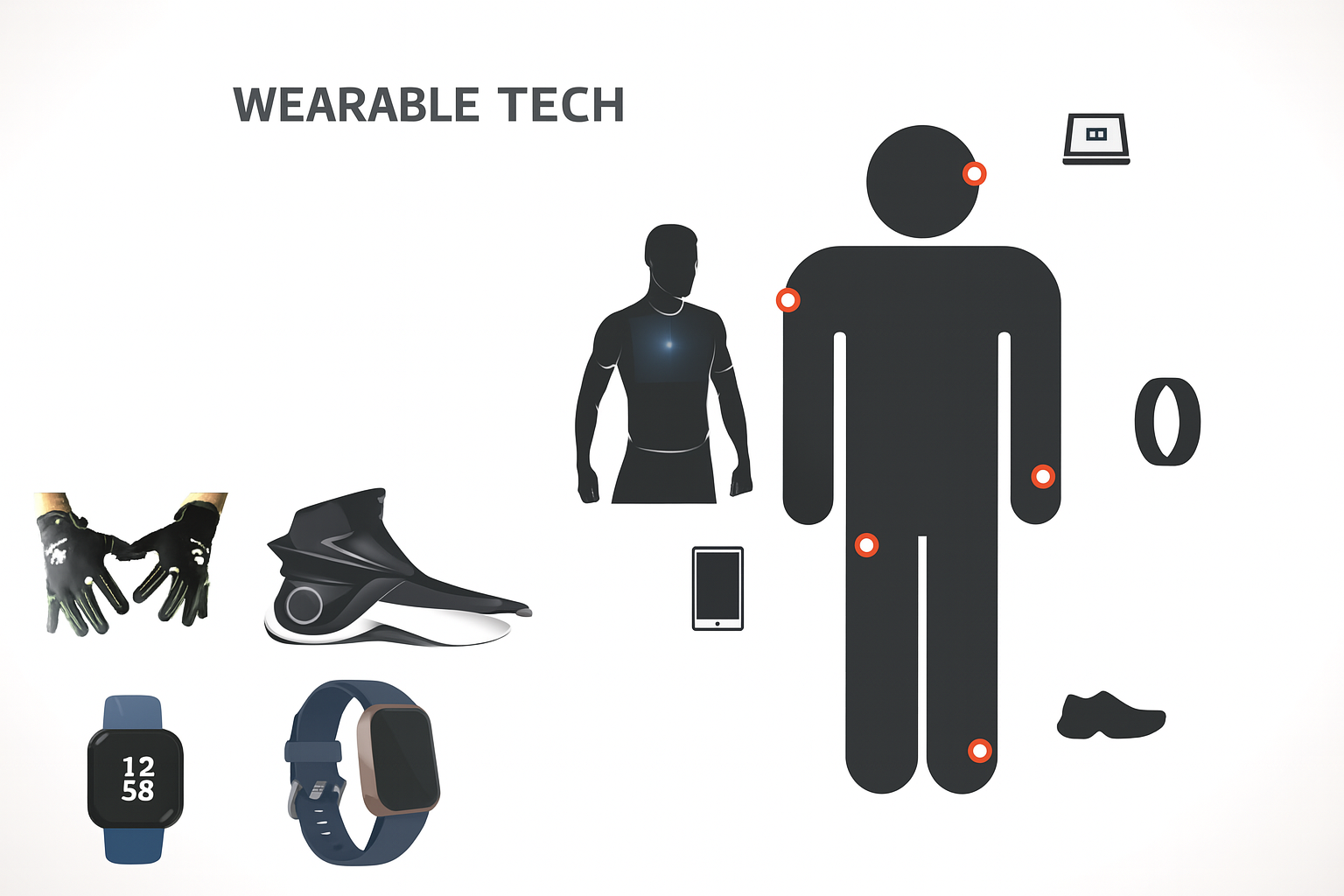

What Is Wearable Technology?

Wearable technology refers to smart devices worn on the body that collect, transmit, and sometimes analyze data. These include fitness trackers, heart rate monitors, smartwatches, AR glasses, and even sensor-embedded clothing. These devices provide real-time feedback, enhance connectivity, and deliver personalized experiences.

As wearable tech becomes smaller and more seamlessly integrated into our daily lives, it demands components that are lightweight, flexible, and durable. This is where printed flexible electronics excel.

Key Innovations Driving Printed Electronics in Wearables

Printed Sensors: Printed biometric sensors can measure heart rate, hydration, temperature, and oxygen levels. These can be embedded in sportswear, medical patches, or bandages for continuous monitoring.

Flexible Batteries: Printed power sources allow wearables to be light, compact, and rechargeable without bulky battery packs.

Smart Textiles: Conductive inks can be printed directly onto fabric to create responsive garments that are washable and capable of detecting motion or pressure.

Wireless Connectivity: Printed antennas and circuitry help link wearable devices to smartphones, cloud platforms, or other IoT networks, enabling seamless data sharing and remote control.

Applications in IoT Wearable Technology

Printed electronics are foundational to the evolution of IoT-enabled wearable devices. They enhance both functionality and form factor in the following ways:

Healthcare Monitoring: Printed biometric sensors in wearable patches allow for continuous patient monitoring, enabling remote diagnostics and reducing the need for in-person visits.

Fitness and Performance: Wearables used by athletes now monitor muscle exertion, sweat, hydration, and body temperature to refine training and optimize recovery.

Workplace Safety: Smart uniforms integrated with printed sensors can alert workers or managers to heat stress, fatigue, or dangerous environmental conditions.

Consumer Electronics: Flexible screens, health trackers, and smart rings rely on printed electronics for compact design and responsive functionality.

Wearable Technology for Athletes: Smarter Training

Athletes are embracing wearable technology enhanced by printed electronics for real-time insights and improved performance. These systems can:

Monitor hydration and electrolyte levels

Analyze muscle stress and movement

Send wireless data to coaches and apps during training or competition

Fit naturally into apparel and gear without limiting motion

This integration helps athletes train smarter, react in real time, and recover faster without bulky devices interfering with performance.

What’s Next for Printed Wearables?

As materials and printing technologies continue to evolve, printed electronics will unlock even more capabilities in wearable technology:

Ultra-stretchable electronics that behave like a second skin

Eco-friendly, biodegradable circuits for disposable health devices

Greater durability for extreme environments or rugged use

Tighter integration with smartphones, apps, and connected ecosystems

Printed flexible electronics are no longer just supporting innovation—they are shaping the future of human-centered technology. They provide a foundation for wearables that are comfortable, data-rich, and nearly invisible.

Whether it's tracking a marathon runner's vitals, improving safety on job sites, or enabling smarter care for patients, printed electronics are transforming what wearable technology can achieve. As the field continues to grow, the boundary between the body and technology is becoming more seamless, ushering in a smarter, more connected future.

Write a comment ...